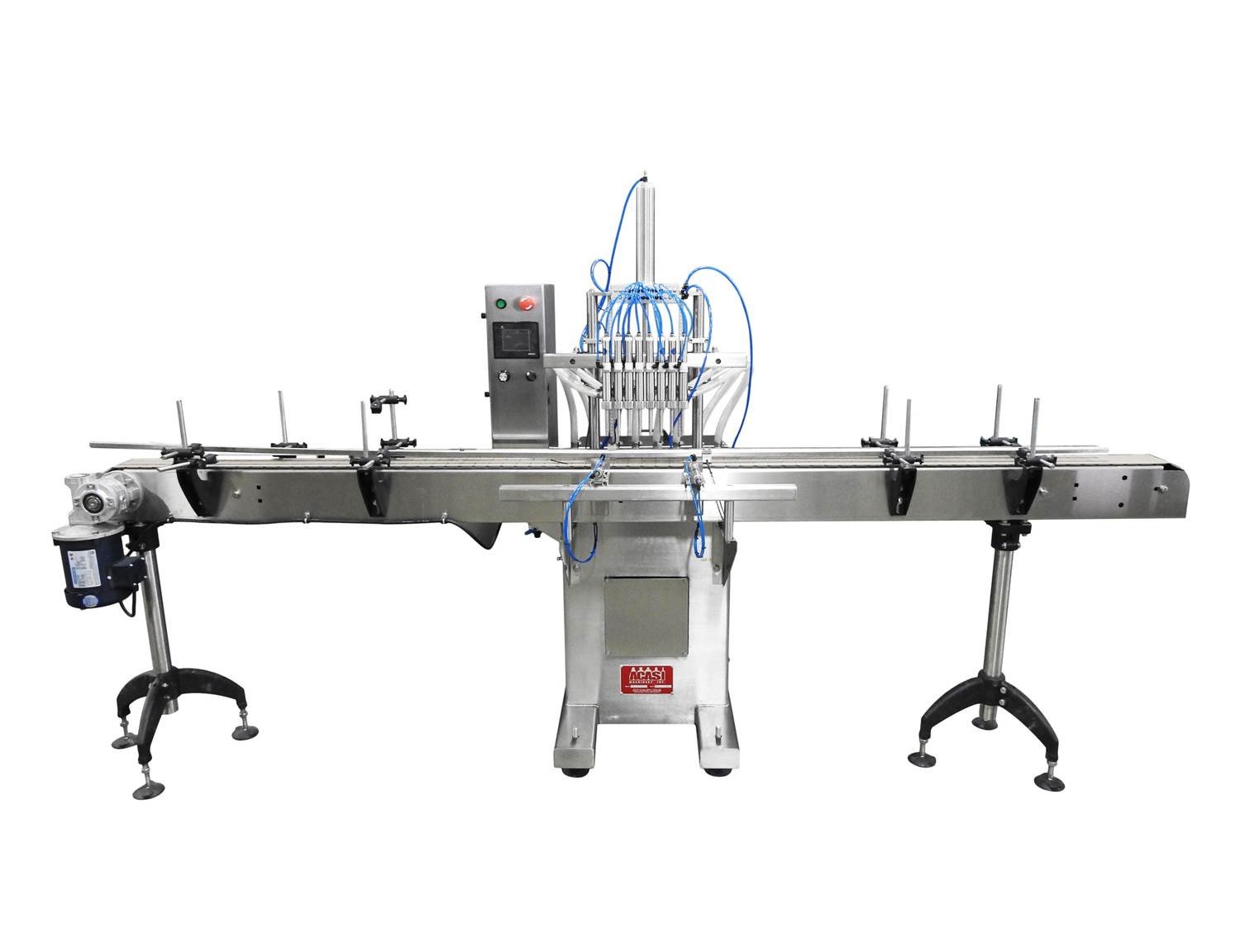

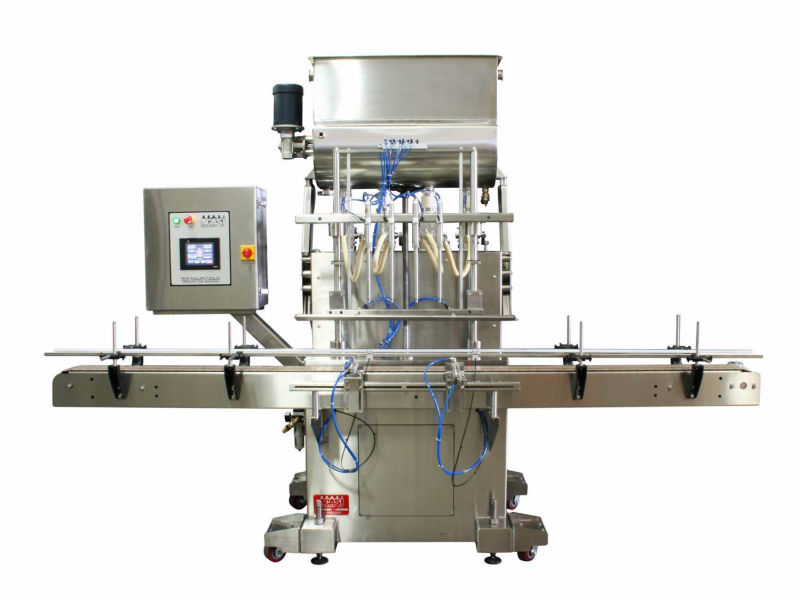

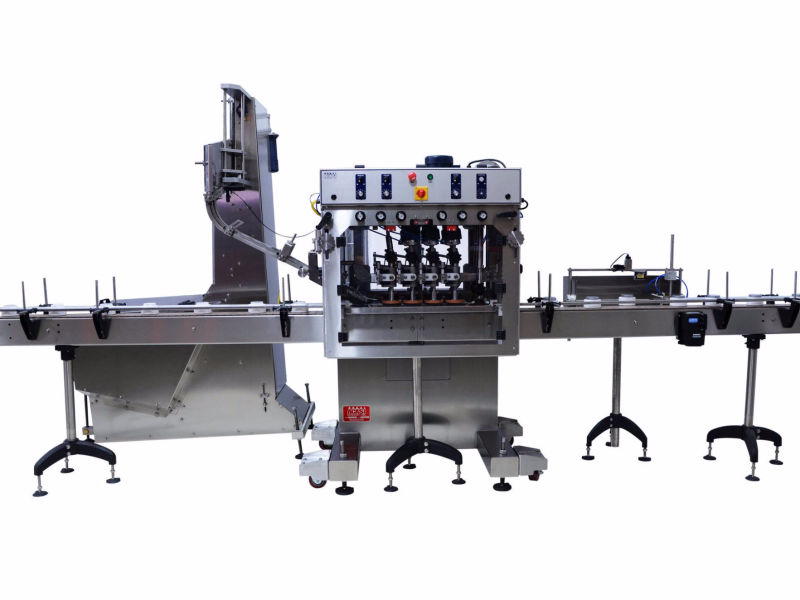

We offer a full range of bottling and packaging equipment for Cosmetics, Creams, Lotions, and Personal Care. From turn-key bottling lines for high viscosity products to individual machines including: bottle unscramblers, piston fillers, cappers (both spindle/quill cappers, as well as chuck cappers), labelers, turn tables, and conveyors.

These machines offer great flexibility and their modularity allows you to build and add to the bottling line as your production needs increase. The machines we offer will help you take the headache off of the bottling process so you can focus on making and selling the best product to your customers.

We can design and make different layouts and conveyor shapes based on your specific floor requirements.