Industries

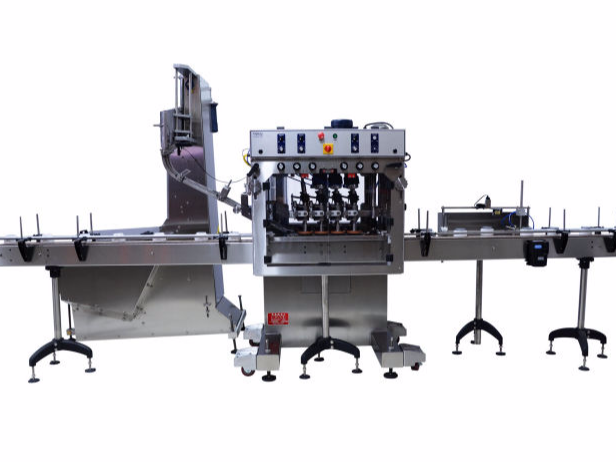

We specialize in the following industries, for which we offer single purpose solutions such as bottle unscramblers, product fillers, container cappers, and labelers, to fully automated production lines.

Chemicals and Cleaners